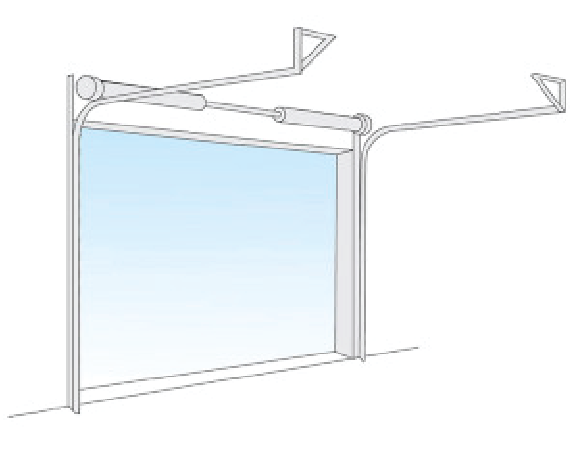

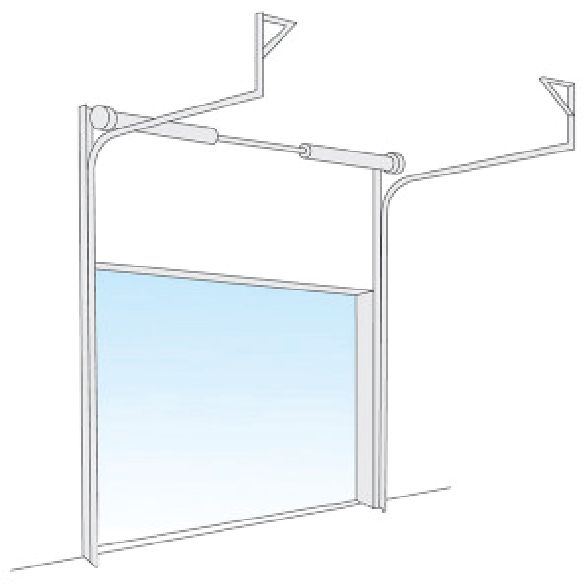

This springless door design enables easier, faster and safer installation. It increases the reliability of opening and closing. And, more importantly, it significantly reduces the risk of both wear and tear, and breakdowns. So, with the DYNACO I-14 DD, your business can keep on running – fast and efficiently.

Your benefits at a glance

- Easier, faster and safer door installation

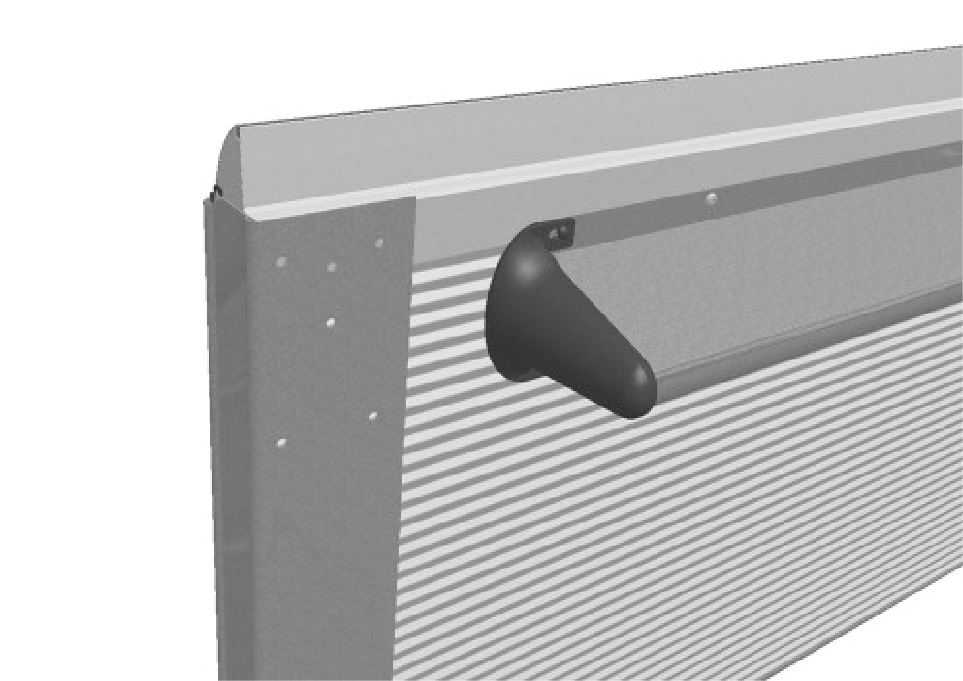

- No spring contamination from rust or dirt

- Reduced wear and tear, and downtime

- High performing electrical direct drive system

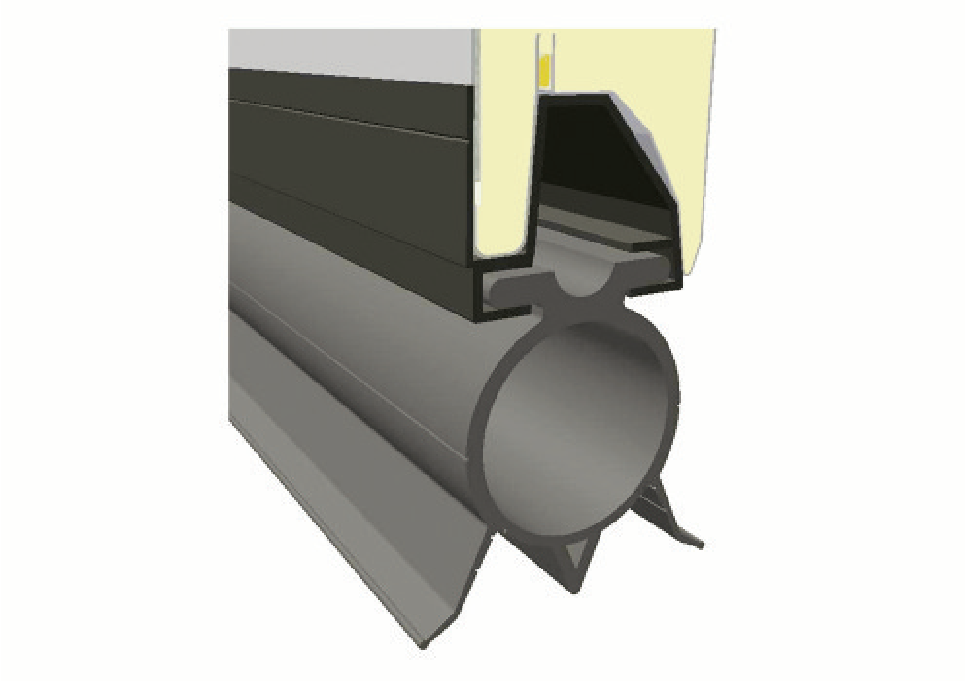

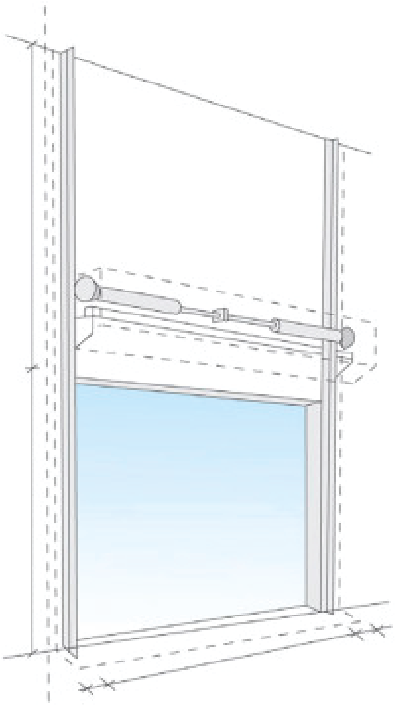

- Class 3 certification for air and water tightness

Heavy-duty demands

Repeated use. Water spray. Corrosive materials. In industrial and commercial operations, overhead sectional doors have to perform in demanding conditions. This can result in a range of problems, including rust and dirt contamination, increased wear and tear, and in worst case scenarios, complete breakdowns.

With the DYNACO OH1042DD, you have a springless, direct drive door that’s ready to keep driving your operations forward – even in the toughest of environments.